ARclad® 9032-70

Product Applications

The typical uses for this product are fabricating EMI shields, electrical interconnections, and ground plane assemblies for cellular phones, computers, PDA’s, disk drives, modems and automotive electronics.

Features and Benefits

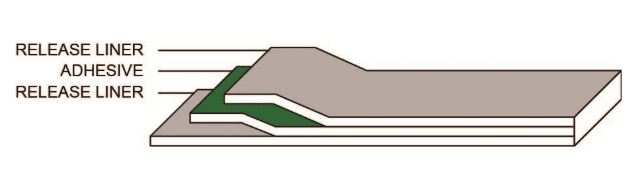

Product Construction

| Typical Values* | Description | |

|---|---|---|

| Liner thickness | 2.0 mil | 51 μm | White PET easy release liner |

| Adhesive thickness | 1.0 mil | 25 μm | Conductive adhesive |

| Liner thickness | 2.0 mil | 51 μm | Clear PET tight release liner |

| Total thickness | 1.0 mil | 25 μm | (Excluding liners) |

*All stated values are nominal and should only be used as a guide for selection. They are not specifications.

Technical Properties

| Attribute* | Typical Values* | Test Method* |

|---|---|---|

| Peel adhesion on stainless steel (180ᵒ, 12 in/min, 1h dwell) |

35 oz/in | 10 N/25.4 mm | ASTM D3330 |

| Release of easy liner (180ᵒ, 300 in/min) |

8 g/2 in | ASTM D5375 |

| Release of tight liner (180ᵒ, 300 in/min) |

38 g/2 in | ASTM D5375 |

| Contact resistance through adhesive (25 °C, 11.5 psi, gold electrodes) |

≤ 10 mΩ | ART 3035 |

| Recommended storage of unconverted product |

70°F ± 20°F | 21°C ± 11°C 50% ± 20% RH | 50% ± 20% RH |

|

| Shelf life of unconverted product | Not to exceed two years from date of manufacture |

*All stated values are nominal and should only be used as a guide for selection. They are not specifications.

Let’s Discuss Your Requirements