ARclear® 44110

Product Applications

The typical use for this product is as a moisture barrier adhesive in various electronics and optical device applications. It is suitable for use in combination with high-barrier films such as inorganically coated plastics. It exhibits good adhesion to a variety of substrates. The adhesive is uncrosslinked and, as such, is not recommended for high-shear and high-temperature applications.

Features and Benefits

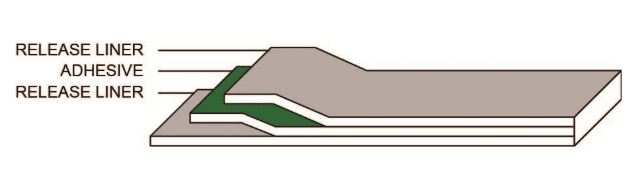

Product Construction

| Typical Values* | Description | |

|---|---|---|

| Liner thickness | 2.0 mil | 51 μm | Clear PET easy release liner |

| Adhesive thickness | 1.0 mil | 25 μm | Optically clear PIB PSA |

| Liner thickness | 5.0 mil | 127 μm | Clear PET tight release liner |

| Total thickness | 1.0 mil | 25 μm | (Excluding liner) |

*All stated values are nominal and should only be used as a guide for selection. They are not specifications.

Technical Properties

| Attribute* | Typical Values* | Test Method* |

|---|---|---|

| Peel adhesion on stainless steel (180⁰, 6 in/min, 1h dwell) |

50 oz/in | 14 N/25.4 mm | ASTM D3330 |

| Peel adhesion on glass (180⁰, 6 in/min, 1h dwell) |

60 oz/in | 17 N/25.4 mm | ASTM D3330 |

| Peel adhesion on polycarbonate (180⁰, 12 in/min, 1h dwell) |

75 oz/in | 21 N/25.4 mm | ASTM D3330 |

| Peel adhesion on PET (180⁰, 12 in/min, 1h dwell) |

68 oz/in | 19 N/25.4 mm | ASTM D3330 |

| Peel adhesion on PMMA (180⁰, 12 in/min, 1h dwell) |

78 oz/in| 22 N/25.4 mm | ASTM D3330 |

| Release of easy liner (180⁰, 300 in/min) |

8 g/2 in | ASTM D5375 |

| Release of tight liner (180⁰, 300 in/min) |

40 g/2 in | ASTM D5375 |

| Refractive index | 1.52 | ASTM D542 |

| Optical properties | Transmission: 100% Haze: 0.4% Clarity: 99.4% |

ASTM D1003 |

| Recommended storage of unconverted product | 70°F ± 20°F | 21°C ± 11°C 50% ± 20% RH | 50% ± 20% RH |

|

| Shelf life of unconverted product | Not to exceed one year from date of manufacture |

*All stated values are nominal and should only be used as a guide for selection. They are not specifications.

Let’s Discuss Your Requirements